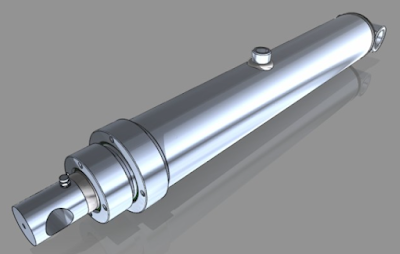

What is Multistage Telescopic Cylinder?

Multistage hydraulic cylinders or telescopic hydraulic cylinders are a recent innovation that have enabled us to customize and enhance the application of various types of machinery. They are used for a wide range of applications including cultivation, construction, and civil engineering. The primary advantage of the multi-stage hydraulic cylinder lies in the extension capabilities of its shaft, allowing it a far longer stroke when compared with other cylinders. It consists of various tubular rods known as sleeves. These sleeves (usually five or six) are of decreasing diameters and are placed within each other. Once pressure is pumped into the cylinder, the largest sleeve (also known as barrel or main) is the first to extend. It is followed by subsequent sleeves up to the last one (known as a plunger) until it reaches its maximum extension. The compact design of the multi-stage hydraulic cylinder allows it to enhance the function of process operations by proving particularly useful